Unsaturated Polyester Resins (UPR)

Unsaturated Polyester Resin For Quartz / Artificial Stone

Our specialized range of Unsaturated Polyester Resins (UPR) is meticulously formulated for the production of high-quality Quartz and Artificial Stone slabs, tiles, and molded products. These resins serve as the crucial binding matrix, delivering the exceptional strength, chemical resistance, and aesthetic clarity required to meet the demands of modern interior and exterior design applications.

Key Performance Advantages

Exceptional Bonding Strength

Superior Clarity and Color Stability

Rapid Processing

High Hardness and Scratch Resistance

Chemical & Stain Resistance

Low Styrene Emission

Ideal Application Areas

Quartz Countertops and Vanity Tops

Artificial Marble and Granite Slabs

Composite Stone Tiles and Flooring

Sinks, Tubs, and Sanitary Ware

Molded Architectural Elements

Pultrusion Terephthalic Resin PTA Resin

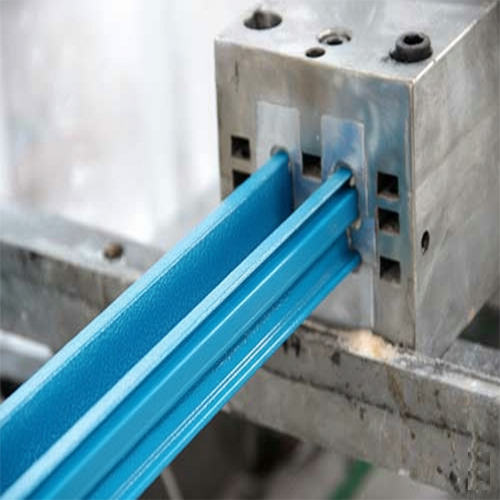

Our Pultrusion Terephthalic Resin (PTA Grade) is a highly reactive, modified unsaturated polyester resin engineered specifically for the demanding process of pultrusion. Its unique PTA backbone delivers exceptional strength, high thermal stability, and consistent curing properties, making it the ideal choice for creating composite profiles that require maximum performance and durability.

This resin ensures superior wet-out of reinforcing fibers, resulting in void-free, perfectly formed profiles at high line speeds, maintaining consistency from start to finish.

Key Features & Advantages

Exceptional Mechanical Strength

Superior Heat Resistance

Advanced Chemical Resistance

Optimized for Pultrusion

Excellent Weatherability

Ideal Applications

Infrastructure

Chemical & Processing

Construction

Electrical

Terephthalic Acid GP Resin (PET)

Terephthalic Acid GP Resin is a General Purpose (GP) unsaturated polyester resin based on terephthalic acid (PET). This type of resin is known for offering enhanced chemical resistance, improved water resistance, and better thermal stability compared to resins based on orthophthalic acid. It is commonly used in applications where moderate performance improvements over basic resins are desired, without the higher cost of isophthalic resins.

Key Features and Benefits

Improved Chemical Resistance

Enhanced Water Resistance

Good Mechanical Strength

Faster Curing Times

Versatile Application

Typical Applications

Marine Components

Pipes and Tanks

General FRP Moldings

Construction

Terephthalic Resin (PTA) (GP)

General Purpose Terephthalic Resin is a medium-viscosity, reactive unsaturated polyester resin based on Purified Terephthalic Acid (PTA). Engineered to bridge the gap between standard Orthophthalic resins and premium Isophthalic resins, this formulation offers a superior balance of mechanical strength, chemical resistance, and cost-efficiency.

Designed for versatility, this resin delivers excellent wetting properties with glass fibers and provides a high-quality surface finish, making it the ideal choice for manufacturers requiring durability beyond standard general-purpose resins.

Key Performance Advantages

Excellent Water Resistance

Improved Chemical Resistance

Enhanced Thermal Properties

Good Mechanical Strength

Typical Applications

Marine Industry

Storage & Piping

Transportation

Construction

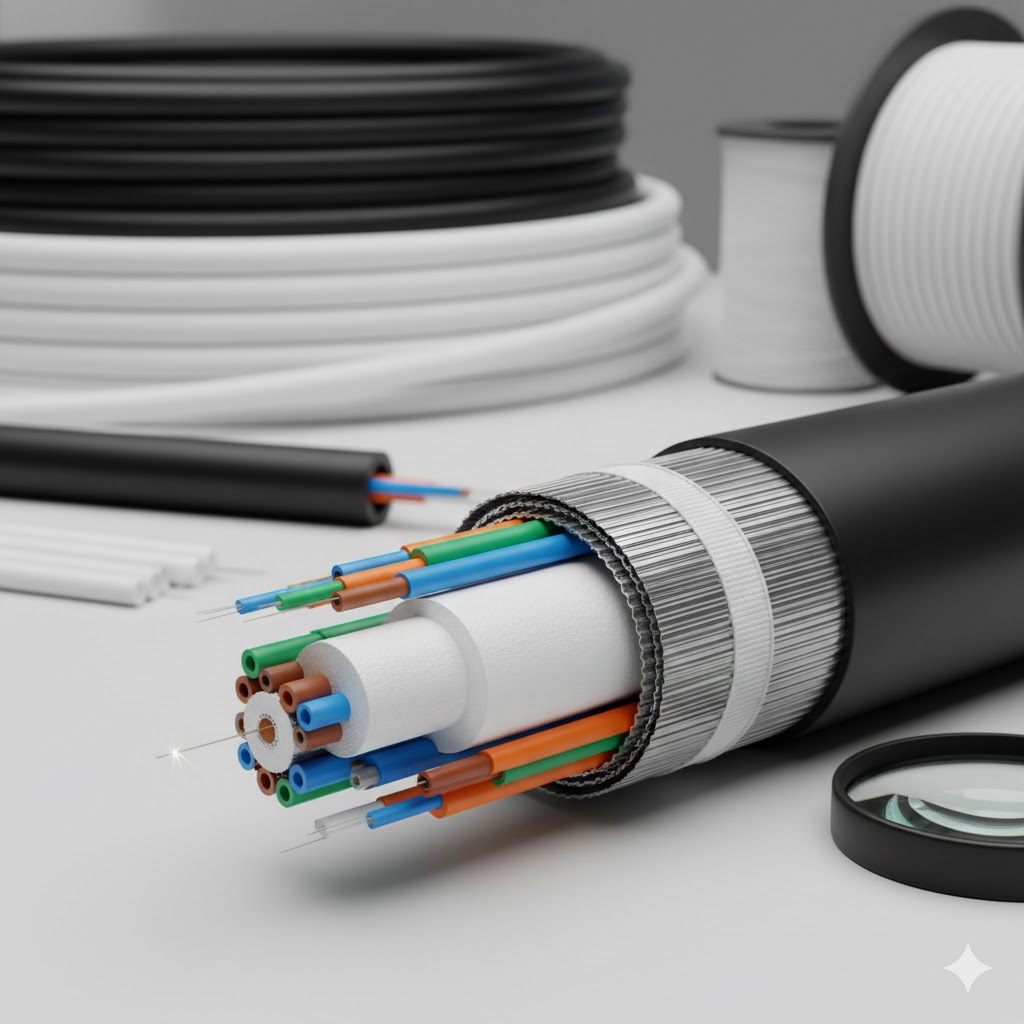

Unsaturated Polyester Resin For Fiber Optic Cables

Our specialized Unsaturated Polyester Resin (UPR) is a high-performance thermosetting matrix specifically formulated for the pultrusion of FRP (Fiber Reinforced Polymer) non-metallic strength members used in fiber optic cables. This resin is engineered to ensure the critical mechanical integrity and long-term durability required to protect delicate optical fibers under extreme installation and environmental stresses.

By utilizing this UPR in the central strength member, cable manufacturers can produce lightweight, highly resilient cables that are entirely metal-free, eliminating concerns related to lightning, corrosion, and electromagnetic interference (EMI).

Key Features and Benefits

High Tensile & Flexural Strength – Provides superior load-bearing capacity and rigidity to the central rod, preventing fiber stretch or micro-bending under tension (e.g., during cable pulling).

Excellent Pultrusion Processability – Exhibits a low-to-moderate viscosity and tailored reactivity profile (short gel time) for high-speed, consistent pultrusion, ensuring uniform resin impregnation and low void content.

High Heat Distortion Temperature (HDT) – Maintains dimensional stability and mechanical strength during and after the pultrusion curing process, and withstands elevated temperatures in harsh operating environments.

Corrosion & Chemical Resistance – Offers robust protection against moisture, water ingress, and common corrosive elements, ensuring a cable life expectancy of 25+ years.

Dielectric Properties – As a non-conductive polymer, it ensures the finished FRP rod is free from electromagnetic induction and is safe for use near high-voltage lines.

Low Cure Shrinkage – Minimizes internal stresses during curing, which is critical for maintaining the tight dimensional tolerances required for the central strength membe

Typical Applications

- FRP Central Strength Member: The primary application, where the resin is pultruded with glass fiber roving to form the rigid, high-strength core of the cable.

- Non-Metallic Peripheral Reinforcement: Used in specific cable designs requiring additional non-metallic stiffening elements.

Orthophthalic Resin

Orthophthalic GP Resin is the most common and cost-effective type of unsaturated polyester resin (UPR), often used as the industry standard for a wide array of fiberglass reinforced plastic (FRP) applications. Derived from orthophthalic acid, this resin provides a reliable balance of mechanical strength, ease of use, and curing characteristics. It is the go-to choice for projects where environmental exposure is moderate and extreme chemical or heat resistance isn’t required.

Key Features and Advantages

Economical

Easy to Use

Good Mechanical Properties

Fast Curing

Versatile

Typical Applications

General Fiberglass Parts

Automotive

Marine (Above Waterline)

Construction

Recreational

Isophthalic Laminating Resin

Our Isophthalic Laminating Resin is a premium, medium-to-high viscosity Unsaturated Polyester Resin (UPR) designed for composite applications demanding superior resistance to chemicals, water, and heat. Formulated using Isophthalic Acid (IPA) as the main diacid, this resin provides performance characteristics significantly beyond standard Orthophthalic or general-purpose Terephthalic resins.

It is the ideal choice for creating high-performance laminates via Hand Lay-up or Spray-up, particularly in environments exposed to moisture or corrosive media.

Key Performance Advantages

Superior Water Resistance

Enhanced Chemical Resistance

Excellent Mechanical Properties

Weathering & UV Stability

Ideal Applications

Marine Construction

Above-Ground Storage Tanks

Automotive & Transportation

Sanitary Ware

Pultrusion & RTM

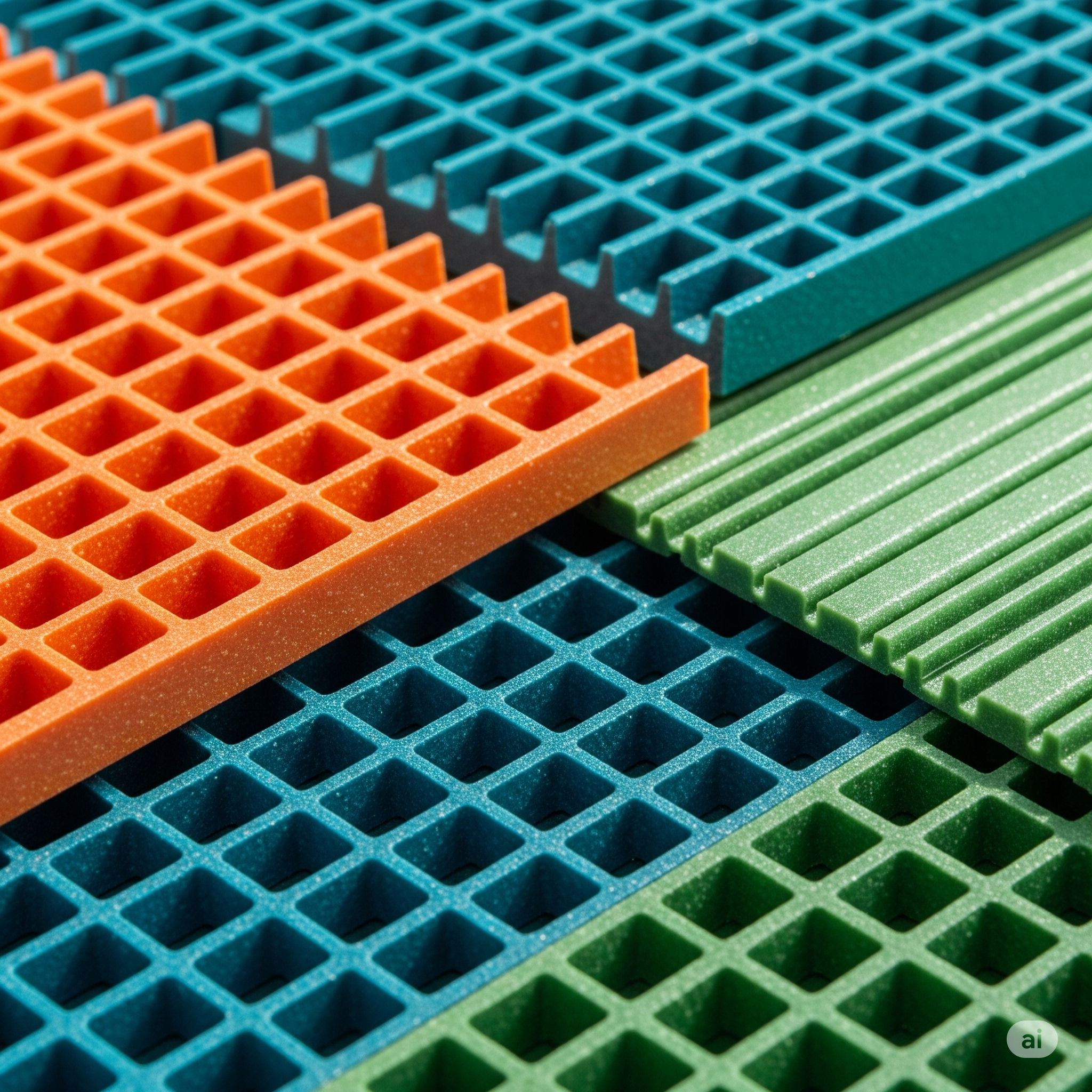

Pultrusion Isophthalic Resin

Our Pultrusion Isophthalic Resin is a high-performance unsaturated polyester resin specifically engineered for the pultrusion process. This resin formulation is based on isophthalic acid (ISO), which provides a significant upgrade in performance over standard orthophthalic resins. It delivers an optimal balance of reactivity, viscosity, and mechanical properties essential for high-speed, continuous manufacturing of consistent profiles.

Key Features & Benefits

Exceptional Corrosion Resistance: The Isophthalic backbone provides robust resistance to a wide range of corrosive chemicals, acidic environments, and constant moisture, making it ideal for wastewater treatment, chemical processing, and marine applications.

High Mechanical Strength: Imparts superior flexural, tensile, and impact strength to pultruded profiles (e.g., beams, channels, rods), enabling their use in load-bearing and structural applications.

Optimized for Pultrusion: Features a low-to-medium viscosity and tailored cure kinetics (gel time) for high-speed line operations, ensuring complete fiber impregnation and minimized void content.

Excellent Surface Finish: Designed to cure with a smooth, glossy surface finish, which improves UV resistance and reduces the need for secondary coating operations.

Superior Thermal Performance: Offers a high Heat Distortion Temperature (HDT), allowing the finished profiles to maintain structural integrity under elevated service temperatures.

Dimensional Stability: Exhibits minimal volume shrinkage upon curing, resulting in high-precision parts with consistent cross-sectional dimensions.

Typical Applications

- Structural Components: Beams, channels, angles, and rods for platforms, walkways, and stairways in corrosive industrial facilities.

- Electrical Applications: Cable trays, switchgear components, and insulation profiles due to its dielectric properties.

- Civil Engineering: Highway sound barriers, bridge components, and rail third-rail covers.

- Wastewater Treatment: Baffles, weirs, and grating where exposure to chemicals and constant moisture is a concern.

Bisphenol-A Epoxy Vinyl Ester Resin

Bisphenol-A Epoxy Vinyl Ester Resin (BPA-VER) is a premium thermosetting polymer that effectively bridges the performance gap between traditional Unsaturated Polyester Resins (UPR) and high-end Epoxies. Synthesized by reacting a Bisphenol-A based epoxy resin with methacrylic acid, it combines the superior chemical and mechanical properties of epoxy with the ease of handling and rapid cure of polyester.

This resin is the globally recognized standard for demanding industrial applications, offering exceptional resistance to aggressive chemicals, high temperatures, and mechanical fatigue.

Key Performance Advantages

Outstanding Chemical Resistance – Provides robust protection against a wide range of organic and inorganic acids, alkalis, salt solutions, bleaches, and solvents.

Superior Mechanical Toughness – Features high elongation, tensile strength, and flexural modulus, resulting in FRP parts with excellent impact resistance and fatigue life.

High Heat Distortion Temperature (HDT) – Maintains structural integrity and mechanical properties under elevated temperatures, making it suitable for hot chemical service.

Low Water Absorption – Offers significantly better hydrolytic stability and resistance to water ingress than standard polyester resins, making it ideal for marine and wet environments.

Excellent Adhesion & Low Shrinkage – Provides strong bonding to fiberglass and carbon fiber, with minimal shrinkage upon curing to reduce internal stress and micro-cracking.

Process Versatility – Compatible with common fabrication techniques due to its manageable viscosity, allowing for rapid and effective glass wet-out.

Ideal Applications

- Chemical Processing Equipment: Storage tanks, reaction vessels, scrubbers, ducts, and pipelines for corrosive media.

- Wastewater Treatment: Tanks, pipes, and corrosion-resistant linings exposed to sewage and chemical compounds.

- Marine Industry: High-performance boat hulls, decks, and repair laminates where resistance to water absorption and fatigue is essential.

- Industrial Linings: Corrosion-resistant flooring, secondary containment, and coatings for structural steel in chemical plants.

Novolac Epoxy Vinyl Ester Resin

Novolac Epoxy Vinyl Ester Resin (NVE) represents the pinnacle of corrosion-resistant thermoset technology. Synthesized from a highly functional Epoxy Novolac backbone, this resin creates a composite matrix with a densely cross-linked structure that far surpasses standard Bisphenol-A Vinyl Ester (BPA-VER) and Unsaturated Polyester Resins (UPR) in performance.

NVE is specifically engineered for critical, heavy-duty applications where equipment is exposed to a combination of strong chemicals, aggressive solvents, and high operating temperatures. It is the resin of choice when material failure is not an option.

Key Features & Benefits

Extreme Solvent Resistance: Unmatched protection against a wide range of organic solvents and chlorinated aromatics (e.g., in mining and chemical extraction).

Oxidizing Acid Resistance: Exceptional integrity against oxidizing acids (like nitric acid, chlorine, and hypochlorites), which rapidly degrade lesser resins.

Very High HDT (Heat Distortion Temperature): The highly cross-linked Novolac structure offers superior thermal stability, retaining mechanical strength and rigidity at elevated service temperatures.

Excellent Mechanical Retention: Maintains high flexural, tensile, and impact strength even after prolonged exposure to heat and corrosive environments.

Low Shrinkage: Minimal volumetric cure shrinkage reduces internal stress, ensuring long-term lining integrity and crack resistance.

Typical Applications

Flue Gas Desulfurization (FGD) Equipment: Linings for scrubbers, stacks, ducts, and chimney liners exposed to hot, wet, acidic, and oxidizing flue gases.

Chemical Storage & Processing: Tanks, pipes, and vessels for concentrated acids (e.g., sulfuric, hydrochloric, hydrofluoric), caustic solutions, and solvents.

Mining & Metallurgy: Equipment exposed to aggressive leaching and solvent extraction processes.

High-Performance Coatings: Used as a binder for glass-flake or reinforced linings on concrete and steel in primary and secondary containment areas.

Oil & Gas: Downhole tubing and components requiring resilience against hot hydrocarbons and harsh chemicals.