Carbon Fiber Fabric

UNIDIRECTION CARBON FIBER FABRIC

Our Unidirectional (UD) Carbon Fiber Fabric is engineered for maximum performance, providing exceptional strength and stiffness precisely where it’s needed. Unlike woven fabrics that distribute load in two directions (±45∘ or 0∘/90∘), UD fabric features nearly all of its carbon fibers aligned parallel in a single direction (0∘ or 90∘). This concentration of fibers maximizes the composite’s tensile and flexural strength along the primary axis of the load.

Key Features and Advantages

Maximum Longitudinal Strength: Achieves the highest possible strength-to-weight ratio by aligning virtually all fibers to carry the load in one direction.

Optimal Stiffness and Modulus: Ideal for applications demanding extreme stiffness, resulting in minimal deflection under high stress.

Precision Engineering: Perfect for building laminate stacks where specific load requirements dictate the fiber orientation (e.g., placing UD layers at 0∘ for bending or 90∘ for hoop stress).

Lightweight Performance: Significantly reduces component weight while maintaining superior structural integrity compared to traditional materials.

Excellent Fatigue Resistance: Provides long-term durability and performance under cyclic loading.

Typical Applications

The concentrated strength of UD Carbon Fiber Fabric makes it indispensable in high-performance and critical structural applications across numerous industries:

Aerospace: Spars, stringers, and primary structural elements requiring directional strength.

Sports Equipment: High-end bicycle frames, ski cores, surfboards, and rowing shells where minimizing weight and maximizing stiffness is key.

Automotive/Motorsport: Chassis reinforcement, drive shafts, and composite leaf springs.

Marine: Masts, booms, and highly loaded structural bulkheads.

Industrial: Repair and reinforcement of civil structures, including bridges and concrete beams (FRP strengthening).

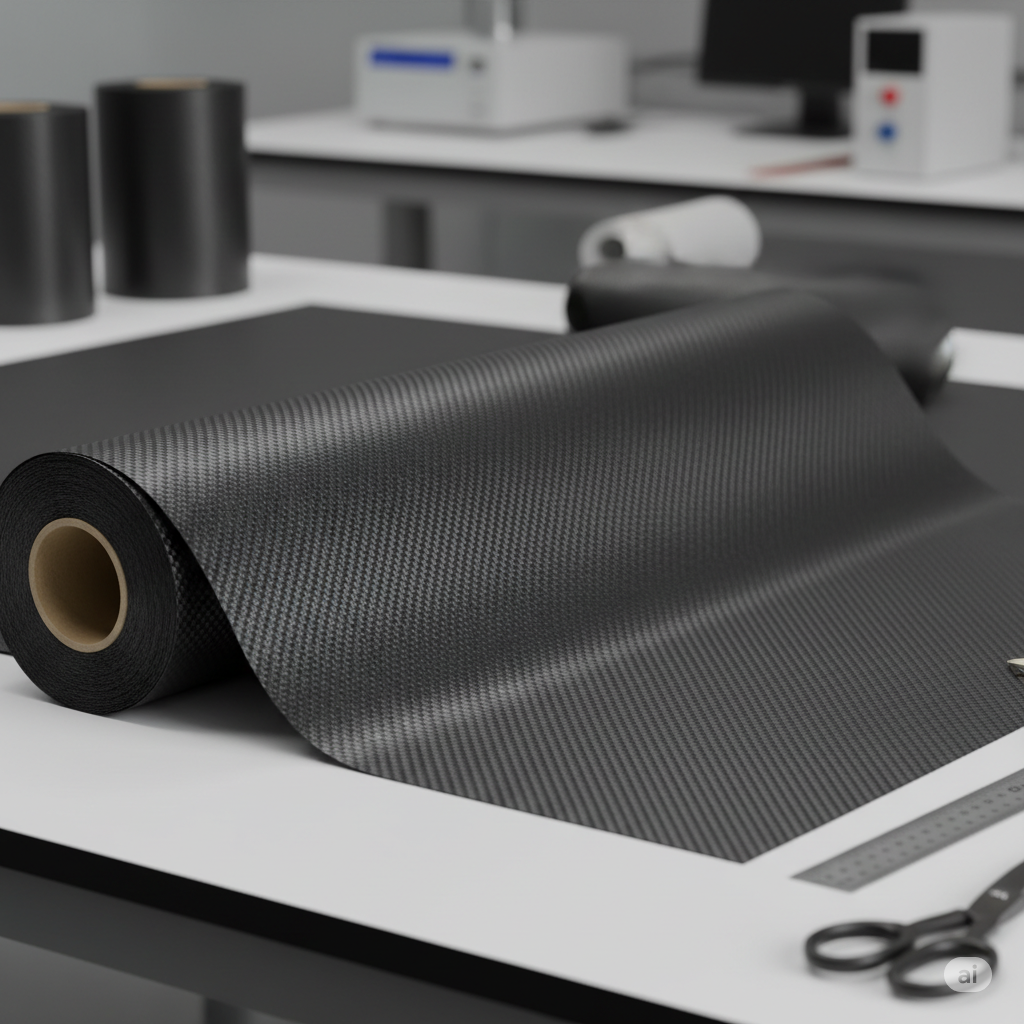

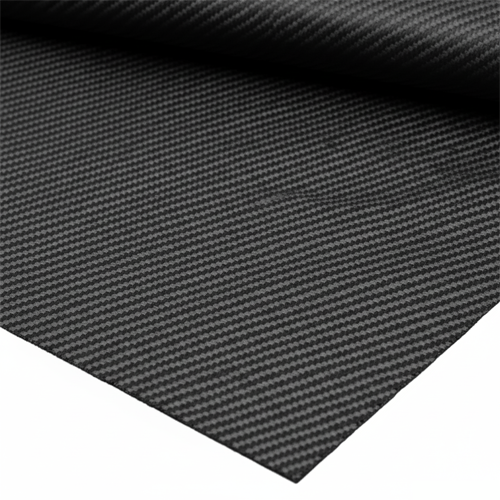

BIDIRECTION CARBON FIBER FABRIC

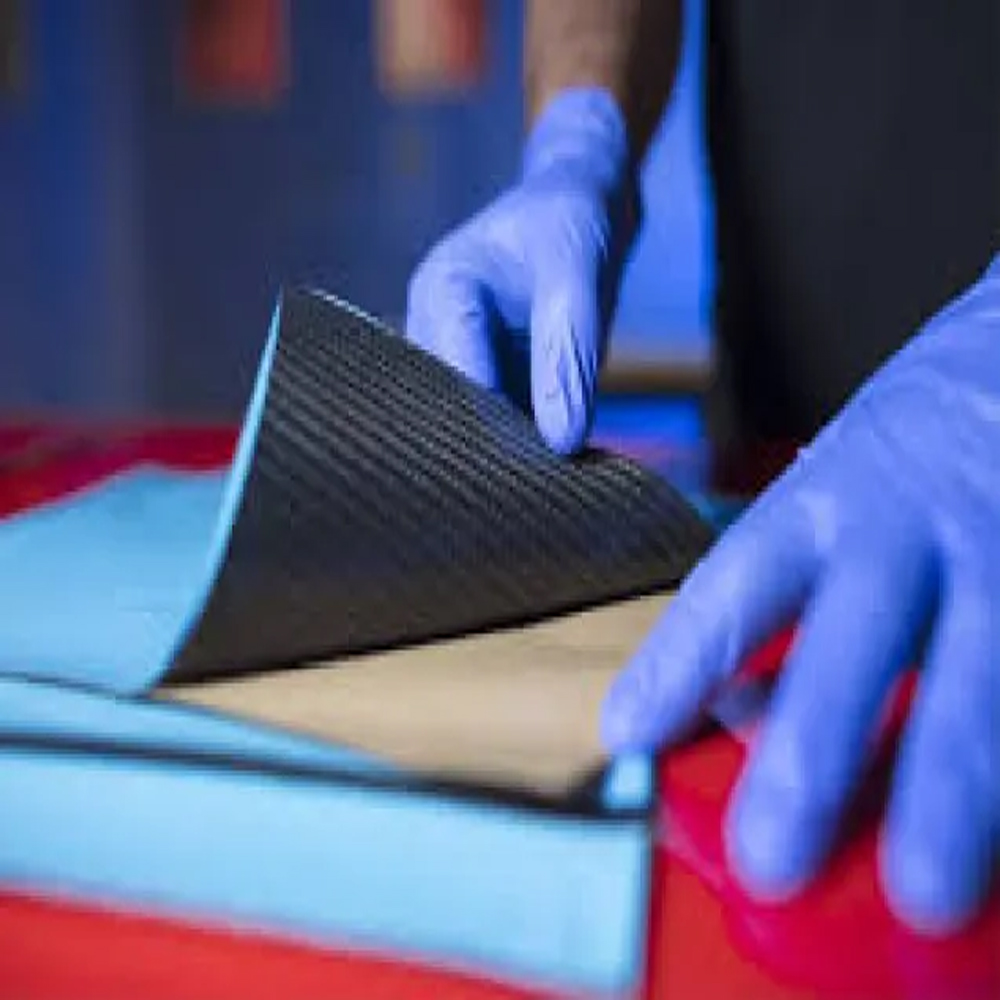

Bidirectional Carbon Fiber Fabric (2×2 Twill Weave)

Our Bidirectional Carbon Fiber Fabric is a high-performance reinforcement material, featuring continuous carbon filaments woven together in both the warp (0∘) and weft (90∘) directions. This balanced construction provides excellent strength and stiffness across two axes, making it highly versatile for composite layups.

Key Features & Benefits

Balanced Properties: Equal strength and stiffness in the two main directions (0∘/90∘), crucial for structural applications experiencing multi-directional loads.

Superior Drapability: The 2×2 twill weave enables the fabric to lay smoothly over contoured shapes with less distortion and wrinkling than plain weaves.

High Strength-to-Weight Ratio: Inherits the exceptional lightweight and high strength characteristics of carbon fiber, ideal for aerospace, motorsports, and performance products.

Aesthetic Finish: Provides the signature, professional “carbon look” when finished with clear resin, making it perfect for visible cosmetic parts.

Compatibility: Works seamlessly with various resin systems, including epoxy, polyester, and vinyl ester resins.

Common Applications

This fabric is the industry standard for creating robust, lightweight, and visually striking composite parts:

Automotive/Motorsports: Body panels, interior trim, air ducts, spoilers, and structural components.

Marine: Kayaks, canoes, and non-primary structural components in boats.

Sporting Goods: High-end bicycle frames, drone components, skis, and protective gear.

Aerospace: Non-critical secondary structures and fairings.

General Fabrication: Custom tooling, prototypes, and high-end consumer products.

PREPREG CARBON FIBER

Our Carbon Fibre Prepreg is a 120⁰C curing Epoxy Prepreg, the resin system exhibits excellent performance in terms of outlife storage and ease of manufacturing. This system can be supplied on a variety of fabrics as per customers’ requirements.

Superior and controlled flow of the resin system makes it suitable for Autoclave, Platen Press and vacuum bagging operations. The tack of the system can be tailor made to meet the customer requirements. Normally ships in medium tack format. This Prepreg system is Available in variety of Carbon and Glass fabrics.

Key Performance Advantages

Cure temperature from 120 to 130⁰C /2 hrs.

Excellent work life of 45 days at 20⁰C

Storage life of 12 months at -18⁰C

Available in variety of Carbon and Glass fabrics and unidirectional Glass and Carbon Ultra-low volatiles (< 0.2%) helps in realizing low void structures

Ideal Application Areas

Aerospace – Aircraft fuselages, wings, interior panels

Automotive – Race car chassis, body panels, spoilers

Sports Equipment – Bicycles, tennis rackets, golf clubs, hockey sticks

Marine – Boat hulls, masts, and performance sailing components

Industrial – Robotics, drones, prosthetics, wind turbine blades

- Consumer Goods – High-end electronics, phone cases, luxury accessories

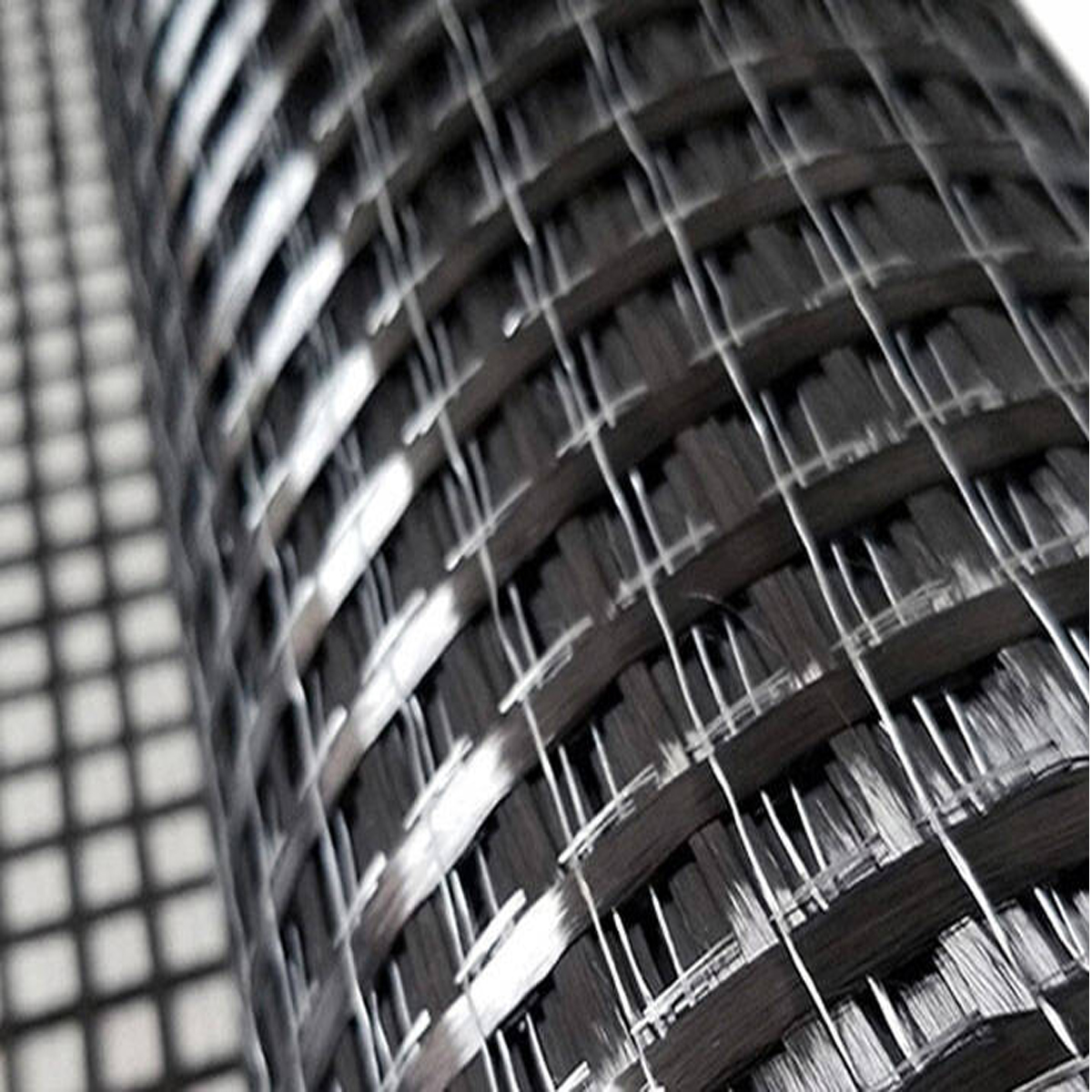

CARBON FIBER REINFORCEMENT GRID FOR CONSTRUCTION

A carbon fiber reinforcement grid is a mesh-like structure made from high-strength carbon fibers embedded in a polymer matrix. These grids are used to reinforce concrete, masonry, and other building materials, offering a lightweight, corrosion-resistant alternative to traditional steel reinforcement.

Key Features & Advantages

- High Tensile Strength: Carbon fibers have tensile strength several times greater than steel.

- Corrosion Resistance: Unlike steel, carbon fiber does not rust, making it ideal for humid, marine, or chemically aggressive environments.

- Lightweight: Reduces structural load and simplifies handling and installation.

- Minimal Concrete Cover: Requires less concrete cover than steel, allowing for thinner structural elements.

- Sustainability: Reduces material consumption and CO₂ emissions due to lower weight and longer lifespan.

- Versatility: Can be used in confined spaces, cold or wet environments, and on vertical or overhead surfaces.

Ideal Applications

Infrastructure: Strengthening bridges, tunnels, aqueducts, and retaining walls

Water Systems: Reinforcing buried tanks, wastewater plants, and sewage systems

Buildings: Seismic retrofitting, column and beam strengthening, masonry wall repair

Industrial: Chimneys, silos, elevator shafts, and corrosive environments